For the German STEIGER® manufacturer – RUTHMANN – the DRS (Dynamic Reach System) ushers in a new era in control technology. For STEIGER® customers, the unprecedented performance capabilities unlock groundbreaking opportunities at the job site.

RUTHMANN brought its first electronic STEIGER® control system to the market 25 years ago.

in 2018 – thanks to digitization – RUTHMANN is introducing DRS.

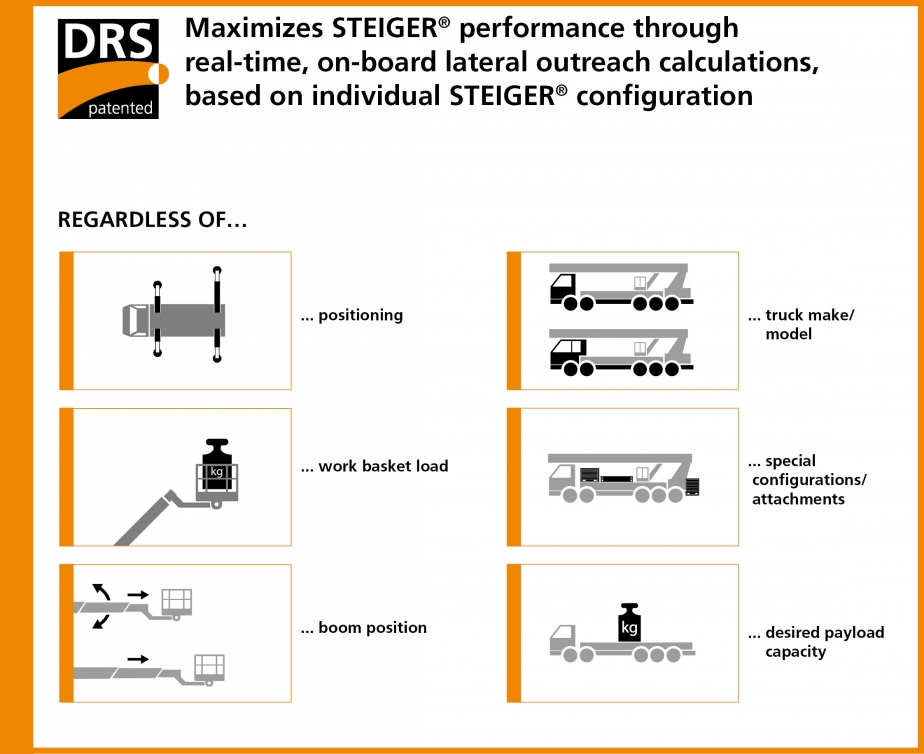

The Dynamic Reach System provides increased working range capacity through real-time, on-board calculations. It is based on the customer’s individual STEIGER® configuration.

The STEIGER® T 900 HF is the first model with the DRS feature. Working-range diagrams illustrate the enormous performance capabilities.

Compared to competitor models in the 90-m category, the magnitude of this "quantum leap" is particularly noticeable. The substantial increase in performance capacity is not a result of additional curb weight, total length, or support base of the work platform. The enhanced performance capabilities are derived from the parameters of the control system. The DRS allocates maximum possible performance parameters for every individual STEIGER® application.

The function of the DRS can be described as follows: The performance capacity – based on the individual assignment – is calculated by the DRS is in real time and shared with the control technology. Each additional "cm" of outrigger height and each reduced "kg" of basket load – and less dynamic boom movement – has a positive impact on the available performance capabilities. With the DRS, motionless set-up and swivel-angle limitations are a thing of the past.

Another added benefit is that with the DRS, customers can choose the truck type, special configurations/attachments, and payload capacity that best suits their own individual needs. For example, customers can order trucks with an additional axle, asking RUTHMANN to refrain from installing ballast weight in order to obtain maximum payload capacity. The parameter settings of the DRS are adjusted to match the required vehicle-body-configuration. The DRS then calculates the maximum performance capabilities for the STEIGER® model.

The DRS provides enormous benefits that cannot be found anywhere else in the industry. It is a quantum leap in RUTHMANN’s control technology.

As of 2019, T 900 HF customers will not be the only ones benefitting from DRS advantages. Over the course of the year, the DRS will also be available on other STEIGER® highflex models. The new working-range diagrams will also confirm the enhanced reach capabilities attained through DRS technology on STEIGER® models in the 50-75 m working-height category.

In short:

The DRS increases the working range, increases reach capacity, and increases the range of application possibilities. This results in a potentially higher utilization rate, increased revenue, and a higher return on investment (ROI). Ultimately, it also leads to higher profits! RUTHMANN's DRS with real-time, on-board calculations, makes it all possible.

RUTHMANN 4.0 – the future has begun.